R&D work on ABS sensor : from growth to characterization

Sensors for car ABS systems

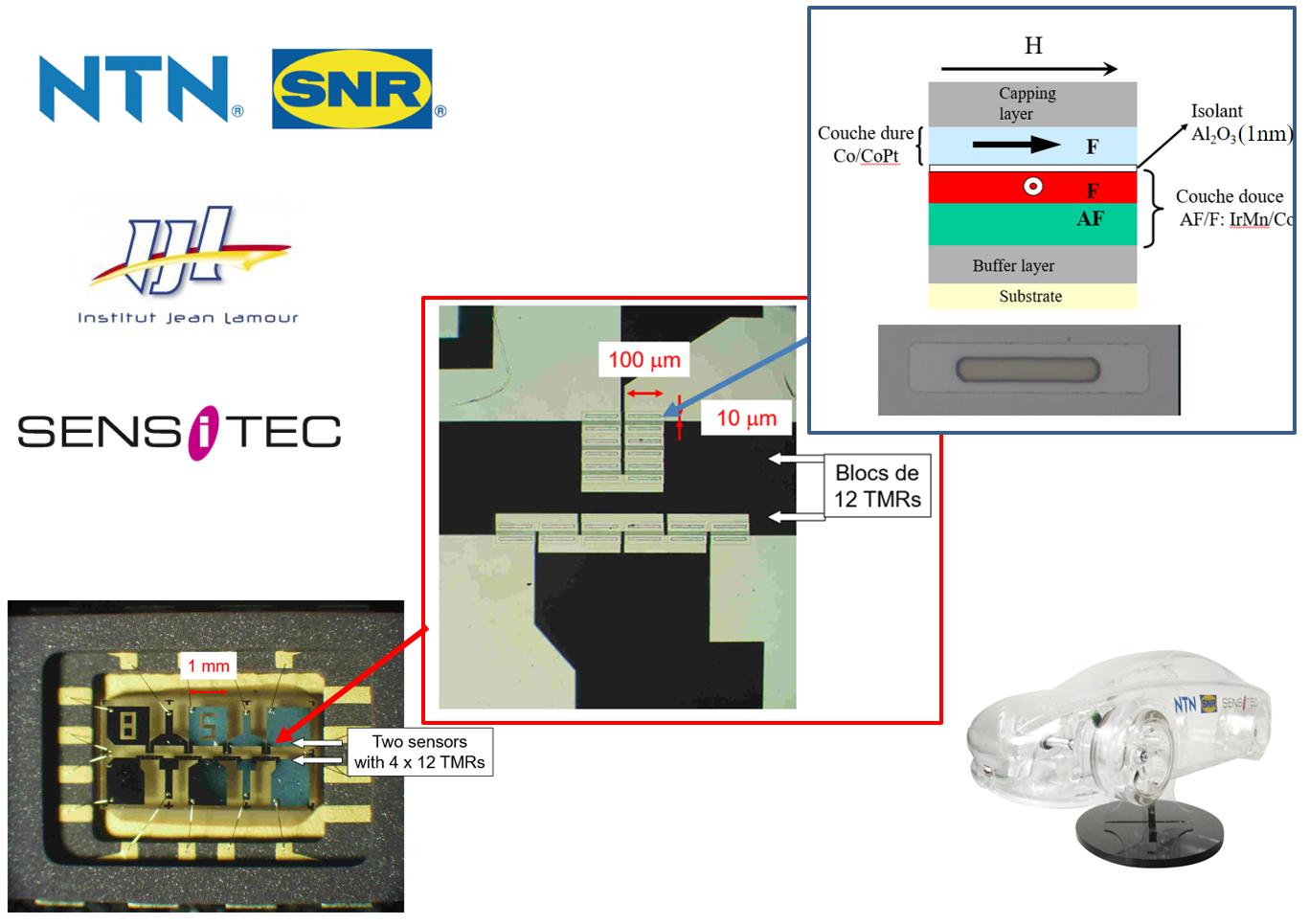

The atomic scale control of magnetic thin film deposition, as well as their structural, magnetic and electrical characterization in micronic and nanometric size systems, has recently enabled the development of new high performance magnetic sensors based on magnetic tunnel junctions. These sensors cover a wide range of needs (HDD read head, speed sensors, etc.). In 2010, Université de Lorraine has worked with NTN-SNR and Sensitec to develop new TMR sensors for cars Active Sensor Bearing (ABS) systems.

New generation of sensors for the next generation of electric vehicles

IMEM-CNR-ASTER has competences in the growth and characterization of soft magnetic films employed in magnetic sensors and magneto-plasmonics. In collaboration with STMicroelectronics, the team has developed and tested a new generation of magnetic flux concentrators in Hall and fluxgate sensors to be employed in the next generation of electric vehicles. The work involved the growth of ultra-soft films on Si substrates and the tailoring of the compositional and morphological features. The team performs film growth by RF-sputtering, and structural (x-ray diffraction), morphological (atomic force microscopy and transmission electron microscopy) and several magnetic characterizations techniques. Nowadays, innovative multilayer magneto-plasmonics films are grown and characterized to be employed in chemical and biochemical magneto-optical sensors.

CRM Group has designed and runs several pilot lines that can be used by customers for testing new production routes, new products or new measurement concepts related to the metal industry.

METAL PRODUCTION LINE IN-SITU CHARACTERIZATION

The measurement systems developed by the CRM Group are devoted to assist industrial operators in controlling processes and ensuring the quality of their products. The harsh conditions in which these systems usually have to operate in the steel industry allow coping with the milder production environments of most other industrial sectors. Through the years, our dedicated staff at CRM Group has developed advanced skills in magnetic measurements, spectroscopy, continuous and pulsed lasers, on-line microscopy, optical design, visible and infrared cameras, specific lighting, home-made electronic hardware and software, data analysis and signal processing, image processing algorithms, real-time and multi-threading software, adapted mechanics, housing and cooling for harsh and hot environment, closed-loop control, etc.